C3 Mini Lathe Bearing Change

A step by step guide to replacing the single row ball bearings fitted to the headstock on the SIEG C3 and similar Mini Lathes with 30206 taper roller bearings. Proper replacement will provide a higher precision finish on your work and reduce or eliminate tool chatter.

For the C3 Mini-Lathe, this project requires the use of a second lathe to make and adjust two plastic spacers in the gearbox so don't start work if you don't have the facilities! The SC2 and SC3 Mini-Lathes are direct belt drive machines so there are no plastic spacers fitted.

1. Start by disconnecting the machine from the mains supply. Remove chuck guard, chuck, gear cover and gear train.

(Note: It is not necessary to remove the leadscrew as shown in the picture - these photos were taken during a complete strip-down of the machine during it's initial preparation for a customer)

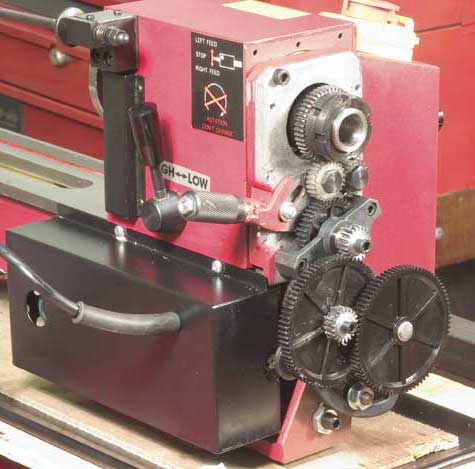

2. Remove belt and layshaft gear.

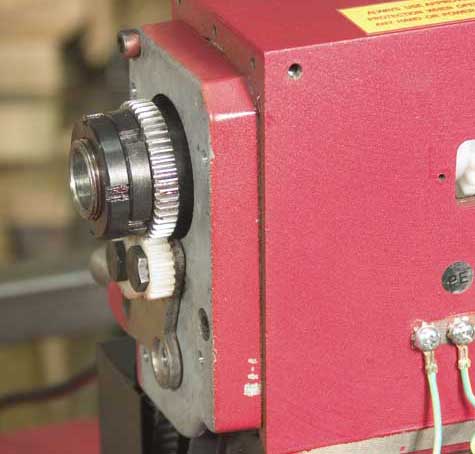

3. Remove the two C-nuts, gear, key, plastic spacer and plastic bearing cover from spindle.

4. Remove the gear cover support bracket and undo the control box but don't disconnect it.

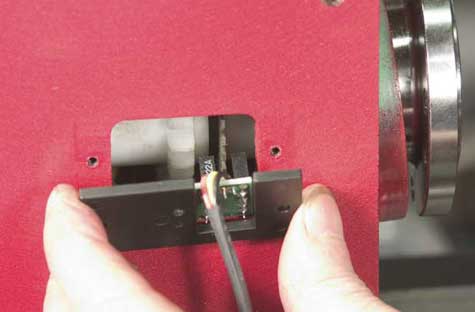

5. Undo the two screws holding the spindle speed sensor and note how the timing wheel fits between the forks of the sensor (some C3 variants are not fitted with a spindle speed display).

6. Working through the holes in the spindle flange, remove the 3 screws from the front bearing cover.

7. Remove the spindle from the headstock using a puller. The diagram below shows a simple to construct puller made with bits from the scrap box.

8. Remove the plastic spacer and key then extract the front bearing from the spindle using a press/mallet.

9. Clean everything thoroughly, replace the bearing cover on the spindle and press on the new bearing inner being careful to press on the bearing race and not the cage! An 8" length of steel tube is handy here but ensure the bore is greater than 30mm to clear the spindle and the O.D. no more than 40mm to clear the bearing cage.

10. Refit the spacer and key to the spindle.

11. Extract the rear bearing from the case.

12. Press or tap into place the new front and rear bearing outer races.

13. To compensate for the wider taper roller bearings it is necessary to make a new plastic spacer (approx. 0.105" wide) with keyway to fit the spindle between the timing wheel and gears.

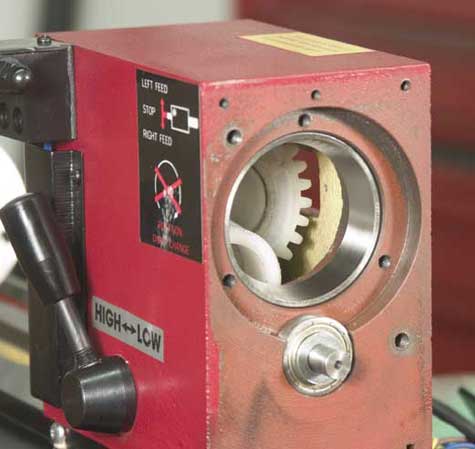

Trial fit the new spacer and adjust as required - the spindle speed timing disk must not foul the pickup and the gears must mesh correctly.

14. Grease front bearing and insert spindle into headstock locating keyed disk, spacers and gears on the key.

15. Fit the rear plastic spacer having first modified it by turning a smaller diameter step at one end so it clears the bearing cage.

16. Grease the new rear bearing and pull it into place using the C-nut, gear and plastic spacer.

17. Temporarily fit the belt cover and check tumbler reverse gear alignment - they probably won't align because the black plastic spacer is now too long.

18. Shorten the black plastic spacer as required.

19. Final adjust the C-nuts using two C-spanners to remove free play and pre-load the bearings.

20. Re-fit the drive pulley, belt and belt cover complete with tumbler reverse.

21. Re-fit gear train, gear cover and chuck.

22. Re-fit the spindle speed sensor (checking again that it clears the timing disk!) and re-fit the control box.

Providing you have no bits left over (except the old ball bearings!) and everything is tightened and adjusted correctly, your lathe is now ready to use.

Copyright © 2017, Arc Euro Trade Ltd. All Rights Reserved.